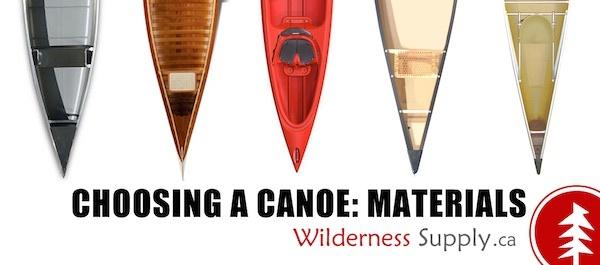

Choosing a Canoe: Materials

Whether you’re looking to buy your first canoe or expand your fleet, deciding on a material is always an important step of selecting your model.

Canoes are available in a wide variety of materials, and each has its advantages (and disadvantages) that make it more suited to specific styles of paddling. Whitewater canoes need to be made of more flexible, durable materials to withstand any bumps or impacts. Flatwater canoes can be made of stiffer, lightweight materials that move quicker over the water and are easier to portage.

There may not be one material that fits the bill for every type of paddling you plan to do, but by matching the weight, impact resistance, efficiency, speed and price of your options to what kind of paddling you plan to do most you can narrow your search to find the best canoe material for your paddling needs.

Wood

| Speed |  |

| Durability |  |

| Weight |  |

| Maintenance |  |

| Cost |  |

Early canoes were all made from wood and bark, as this was the material most available. Cedar strip or canvas-covered wood frame canoes are still available, but are now usually custom-made (and priced accordingly).

Wooden canoes tend to be quite heavy, and require regular maintenance to keep them looking and paddling beautifully over the years. If you don’t enjoy the maintenance part of paddling, you may do well to purchase an alternate material!

Aluminum

| Speed |  |

| Durability |  |

| Weight |  |

| Maintenance |  |

| Cost |  |

At one time aluminum was considered the most advanced material in canoe construction, however technological advances over the last few decades have offered many superior alternatives, and the price has risen dramatically from the few manufacturers still offering aluminum models.

Aluminum canoes are constructed of two sheets riveted together from the inside along the keel. They require very little maintenance, and are not affected by the sun’s UV rays, which makes them a great choice for outfitters and rental operators who want to leave their boats out in the bush between uses.

Though very durable, when dented aluminum will never return to its original shape and any holes need to be fixed by an expert welder. Aluminum canoes are heavy, slow, and noisy since they echo every slap on the water. They are cold to touch in cool weather and can get very hot on the legs in the summer sun! They are not recommended for river paddling, as aluminum sticks to rocks rather than slipping over them.

Plastics

| Speed |  |

| Durability |  |

| Weight |  |

| Maintenance |  |

| Cost |  |

Most plastic canoes are made from polyethylene, an inexpensive form of plastic that can be thermo molded to reach a desired shape. However this process limits the variety of shapes available, and as a result polyethylene canoes often have wide entry lines with poor speed and efficiency. Without reinforcement polyethylene lacks stiffness, which also negatively impacts speed. Some lower quality canoes will stiffen the plastic by using a metal bar along the inside keel line – but this adds even more weight and should be avoided in favour of designs where the bottom comes to a “V” in the middle to create extra strength.

Polyethylene canoes are low cost and durable but very heavy, and not suitable for portaging or regular lifting on and off docks. Polyethylene had high impact resistance and slips over rocks without sticking. They require very little maintenance but can be damaged by prolonged exposure to the sun’s UV rays.

Royalex

| Speed |  |

| Durability |  |

| Weight |  |

| Maintenance |  |

| Cost |  |

For years Royalex has been the go-to material for most casual canoe buyers. Lighter than polyethylene and with more variety of design than aluminum, Royalex is essentially a plastic sandwich made of layers of vinyl, plastic and rigid foam. The resulting canoes were exceptionally tough, durable, and quiet, and much lighter than aluminum or plastic models.

Unfortunately despite Royalex’s ubiquity in the canoeing world all sheets for canoe manufacture were produced in one single plant in Indianna. When manufacturers Uniroyal were bought out by international plastics company PolyOne in 2014 all production of Royalex was halted.

Some shops (including Wilderness Supply!) still have some remaining Royalex models available for sale, but as no new canoes are being produced these will quickly disappear, and paddlers are beginning to look to alternative materials for their needs.

TuffStuff

| Speed |  |

| Durability |  |

| Weight |  |

| Maintenance |  |

| Cost |  |

Exclusive to Nova Craft Canoes, TuffStuff is a new material developed in response to diminishing Royalex supplies. Made from composite Basalt/Innegra cloth covered in high impact-resistant vinylester resin, TuffStuff canoes are incredibly durable. Nova Craft has taken much joy in demonstrating their resilience by jumping on canoes, hitting them with a sledgehammer, and dropping one off a ten-storey roof!

Beyond strength, TuffStuff canoes offer other advantages over conventional thermoformed plastic canoes. They are much stiffer, which leads to greatly improved performance and efficiency - the easy glide motion and faster response is noticable after only a few paddle strokes. TuffStuff is also lighter than conventional plastic boats.

Fiberglass Composites

| Speed |  |

| Durability |  |

| Weight |  |

| Maintenance |  |

| Cost |  |

The term ‘composite’ is generally used when speaking of canoes that are built using layers of fabric cloth infused with resin such as epoxy or vinylester. They can be designed in nearly any shape imaginable, and are usually layered by hand using a mold. When left to harden and cure, the result is a stiff and lightweight canoe that is very strong.

Fiberglass composites tend to feature an outer gel coat that provides an extra level of abrasion resistance. This colour pigmented polyester resin is the “first line of defence” and may require some maintenance over time if it is dropped or chipped on a rock. As with most composite canoes, Fiberglass models are known for their stiffness and sharp entry and exit lines, providing high speed and efficiency.

Kevlar Composites

| Speed |  |

| Durability |  |

| Weight |  |

| Maintenance |  |

| Cost |  |

The term ‘composite’ is generally used when speaking of canoes that are built using layers of fabric cloth infused with resin such as epoxy or vinylester. They can be designed in nearly any shape imaginable, and are usually layered by hand using a mold. When left to harden and cure, the result is a stiff and lightweight canoe that is very strong.

Kevlar fibers are stiffer and lighter than fiberglass with higher tensile strength. This means that Kevlar canoes tend to be stronger than fiberglass, and about 25% lighter. Some Kevlar models feature a coloured gel coat just like fiberglass models, however specialized Kevlar canoe manufactures (like Souris River) often colour the Kevlar fabric directly and apply a stiff epoxy to create a stiffer and longer lasting finish that will not scratch over time.

Kevlar canoes are perfect flatwater tripping boats, with extremely high efficiency and very low weight that makes them easy to portage.

*Note that all speed/durability/weight/maintenance/cost ratings are based on averages for their respective materials, and will vary among specific brands and models. Always speak to a trained representative for the best information on any specific boat.